Preventiehiërarchie

Combineren en optimaliseren.

Inhoudsopgave

Wat is preventiehiërarchie?

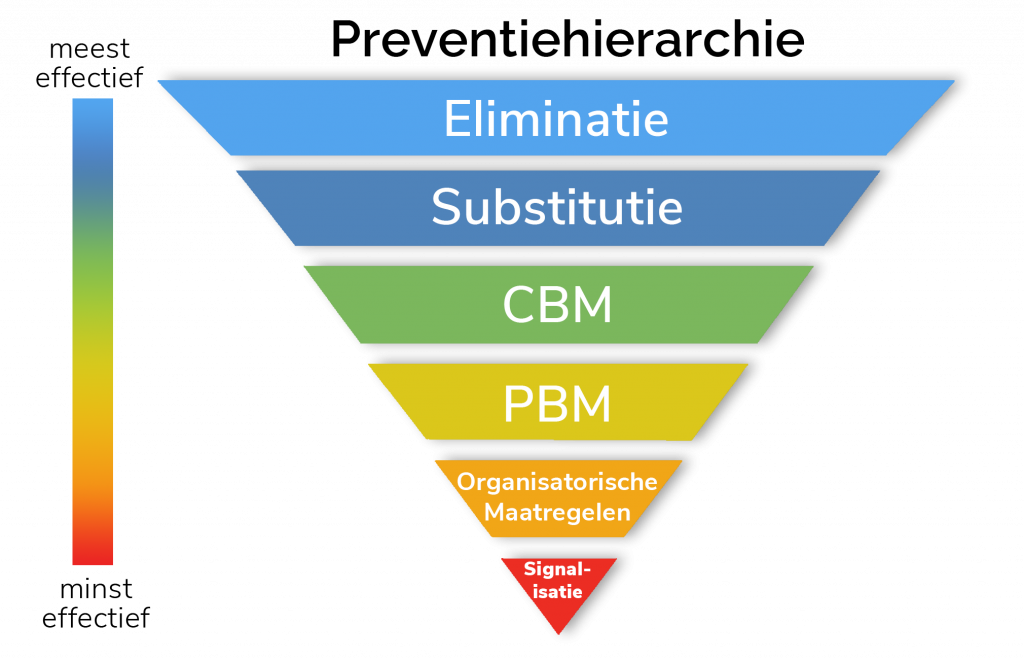

Deze hiërarchie vormt een cruciaal aspect van de redenering die in de preventie wordt toegepast: het volledig elimineren van het gevaar is altijd beter dan het verminderen ervan.

De redenering van de preventiehiërarchie

Hoewel het ideaal is om gevaren volledig te elimineren, is dit in de praktijk vaak niet haalbaar. Vaak is het gevaar een cruciaal onderdeel van het bedrijfsproces. Denk bijvoorbeeld aan heftrucks, reachtrucks, lasersnijders, CNC-apparaten, en lasapparatuur die een essentiële rol spelen in de bedrijfsactiviteiten.

De preventiehiërarchie voorziet daarom een lijst van verschillende categorieën die stap voor stap worden doorlopen om geschikte oplossingen te vinden.

Het concept is eenvoudig: hoe hoger de maatregel in de hiërarchie, hoe effectiever deze is. Het is echter belangrijk op te merken dat een hoger niveau niet noodzakelijk een lager niveau uitsluit; een combinatie van verschillende categorieën versterkt het preventiebeleid.

De niveaus van de preventiepiramide

De verschillende niveaus worden beschreven, met concrete voorbeelden uit de praktijk.

Niveau 1: Eliminatie van het gevaar

Verschillende lagen van de piramide omvatten diverse categorieën van maatregelen.

Een ervaren preventieadviseur is meestal goed bekend met deze structuur, maar het kan waardevol zijn om de verschillende opties op te schrijven en ze te categoriseren voor een optimale besluitvorming.

Het elimineren van het risico/gevaar is ideaal, maar helaas niet altijd haalbaar.

Niveau 2: Substitutie van het gevaar

Als volledige eliminatie niet mogelijk is, is substitutie of vervanging vaak een goede aanpak. Dit betekent eenvoudigweg het vervangen van een gevaarlijk werkmiddel door een alternatief met vergelijkbare functionaliteit maar met minder negatieve impact op veiligheid en gezondheid.

Een praktisch voorbeeld hiervan is het vervangen van een open snijmes door een speciaal ontworpen mes met een verborgen snijvlak voor het openen van dozen.

Een ander illustratief geval is de vervanging van asbesthoudend isolatiemateriaal, nu dit verboden is. Er zijn diverse substituten beschikbaar op de markt, zoals glaswol, rotswol, PUR/PIR schuim, en gespoten isolatiematerialen. Deze alternatieven zijn over het algemeen minder schadelijk en veiliger dan asbest, maar het is belangrijk op te merken dat ze andere unieke risico’s met zich kunnen meebrengen, zoals het risico op inhalatie van stof, huidirritatie, of het gebruik van oplosmiddelen en lijmen bij spuitisolatie.

Substitutie kan het gevaar verminderen of gedeeltelijk wegnemen, maar het is belangrijk om geen nieuwe risico's over het hoofd te zien.

Niveau 3: Collectieve beschermingsmiddelen

Deze laag omvat technische middelen die een gevaar afschermen van individuen, zoals aangehaald in de Codex, boek IX Titel 1.

Dit kunnen omkastingen van machines zijn, afzuiginstallaties voor stof, leuningen bij valgevaar, en andere technische oplossingen.

Het brede beschermende bereik van deze voorzieningen biedt aanzienlijke voordelen, aangezien één enkele voorziening meerdere personen kan beschermen.

Een afzuigapparaat is bijvoorbeeld in staat om iedereen in de bedrijfshal te beschermen tegen ingeademde stof, en niet enkel de actuele gebruiker van bijvoorbeeld een zaagtafel of CNC-apparaat.

Deze middelen beschermen meerdere personen tegelijk en werken rechtstreeks op de oorzaak van het gevaar.

Niveau 4: Persoonlijke beschermingsmiddelen

Wanneer collectieve middelen niet alle werknemers beschermen, komen persoonlijke beschermingsmiddelen in beeld. Dit wordt uitgebreid beschreven in Boek IX Titel 2 van de Codex.

Deze moeten voldoen aan technische eisen, regelmatig onderhouden worden en effectief gebruikt worden waar nodig.

Vaak zijn aanvullende persoonlijke beschermingsmiddelen nodig naast bestaande collectieve maatregelen.

Bijvoorbeeld, een omkasting beschermt werknemers in een nabijgelegen kantoor tegen het geluid van een industriële installatie, maar toch moeten operators die dichtbij komen gehoorbescherming dragen. Er wordt ook vaak gewerkt met een combinatie: iedereen wordt bijvoorbeeld verwacht een helm en veiligheidsschoenen te dragen op de werkvloer, maar iemand die met perslucht werkt moet ook een veiligheidsbril en handschoenen dragen.

Combineer de unieke eigenschappen van collectieve en persoonlijke beschermingsmiddelen om de veiligheid te optimaliseren.

Het persoonlijke aspect vormt echter een zwaktepunt. Ondanks dat de middelen beschikbaar zijn, blijft het de verantwoordelijkheid van de werknemer om ze consequent te gebruiken waar nodig. Daarom is het van groot belang om voortdurend bewustwording te creëren en een veilige werkhouding aan te moedigen.

Niveau 5: Schadebeperkende maatregelen

Deze maatregelen worden toegepast nadat schade al is opgetreden. Het doel is niet om schade te vermijden, maar om het te beperken.

Daarom staat deze categorie zo laag in de hiërarchie, omdat de kerngedachte van de preventiehiërarchie gericht is op preventie, niet op het indammen van al opgelopen schade.

Enkele concrete voorbeelden van schadebeperkende maatregelen zijn:

- Een EHBO-post om de schade van letsel te verminderen, zoals bloedingen, brandwonden, en schade door zuren/bijtende middelen.

- Strooi/absorptiekorrels om milieuschade in te perken, bijvoorbeeld bij olielekken, brandstoffen, en andere schadelijke stoffen.

- Een evacuatieplan bij calamiteiten, zoals brand, explosie, contaminatie, enzovoort.

- Een brandblusser, strategisch geplaatst bij lasinstallaties, oplaadstations, zware apparaten, en dergelijke.

Het is van groot belang om te beseffen dat schadebeperkende maatregelen enorm belangrijk zijn.

Hoewel iedereen hoopt dat ze nooit een schadebeperkende maatregel nodig zullen hebben, benadrukt dit juist de essentie van het voorzien van deze maatregelen.

Ze kunnen een aanzienlijk verschil maken in de impact van een ongeval.

Niveau 6: Signalisatie

Signalisatie komt in beeld wanneer alle andere niveaus zijn doorlopen. Het is ideaal om overgebleven risico’s aan te geven.

Signalisatie kan diverse vormen aannemen, en hier zijn enkele voorbeelden:

- Aanduidingen voor valgevaar (zwart/geel of rood/wit gestreept).

- Pictogrammen met betrekking tot persoonlijke beschermingsmiddelen / PBM's (gehoorbescherming, helmplicht, enz.).

- Gevaarsborden die wijzen op hoogspanning, pletgevaar, en andere risico's.

- Aanduiding van "veilige" en gevaarszones, met groene/rode vlakken op de vloer.

Een doeltreffende signalisatie is van cruciaal belang voor de veiligheid van zowel werknemers als bezoekers, inclusief tijdelijke en nieuwe arbeidskrachten.

Combineren is de boodschap

Het is van groot belang om aan elke categorie de nodige aandacht te schenken. Als eliminatie niet mogelijk is, is het raadzaam om verschillende methoden en middelen in te zetten om het resterende risico optimaal te minimaliseren.

Aarzel niet om hulp te vragen aan een externe expert, zoals een ervaren preventieadviseur of veiligheidsconsultant, die op de hoogte is van de laatste ontwikkelingen op het gebied van maatregelen, middelen en regelgeving.

Bronvermelding | meer informatie

Op zoek naar duidelijkheid?

Wat zijn alle mogelijke maatregelen? Welke middel rendeert het beste? Wat kost het aanbrengen van signalisatie? Hoeveel brandblussers moet ik voorzien? Wat moet ik allemaal laten keuren? Wie kan er veiligheidsopleidingen geven?

Prevom heeft oplossingen op maat:

Wij informeren u graag over de mogelijkheden!